Free Shipping

Need quick shipping please call 01296326111

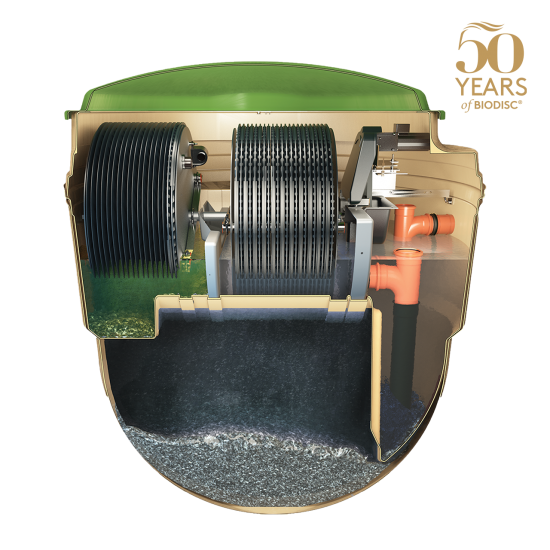

Klargester Biodisc BB Internal Pump System (Suitable for 12 People)

NOW WITH 7 YEARS WARRANTEE

The Klargester BioDisc is the only sewage treatment plant to utilise the "Rotating Biological Contactor" (RBC) system to achieve the breaking down of pollutants plus generation of aerobic bacteria. This cost effective and adaptable solution to a range of domestic waste treatment requirements has been developed by Klargester over some 25 years.

The RBC system is designed and engineered in order to offer superior levels of reliabilty together with extremely low running costs – it is suitable for a wide range of applications.

Here are some of the many applications where the BioDisc system can be used:

- Domestic dwellings

- Farms

- Pubs, Clubs & Hotels

- Housing Estates

- Offices

- Industrial Estates

- Schools, Colleges

- Nursing & Care Homes

- Caravan & Leisure Parks

We are celebrating 50 years of the Klargester Biodisc.

In honor of our celebration, we've distributed numerous Golden Tickets within the lid of our Domestic BioDisc. If you've discovered one of these Golden Tickets, simply register to stand a chance to win fantastic prizes such as holiday vouchers, shopping vouchers, and Klargester merchandise. Kindly fill out your information below to be entered into a draw for our spot prizes.

Low energy consumption (only 50 watts).

Stable process, the BioDisc gives great performance by producing high levels of purification even under high loads.

Certified to EN12566-3 producing 95% pollution reduction - configured to produce a final effluent quality of 20 mg/l BOD5 (ATU)

Biochemical Oxygen Demand, 30 mg/l suspended solids.

Variable invert options for shallow and deep installations.

BioDisc units are composed of a series of connected reactors and chambers:

BioDisc BA-BG are self contained, single piece units.

BioDisc BA-BE are available with varying inlet depths to meet varying site levels.

The main structure of the BioDisc unit is made using Glass Reinforced Plastic (GRP) which makes them tough and durable. The 'business end' of the units is of course where the biological action takes place – this treatment happens on the Rotating Biological Contactor, sometimes referred to as the Rotor, in the BioDisc.This rotor is made from banks of polypropylene discs (called 'media') attached to a horizontal, zinc coated steel shaft which in turn is rotated slowly by an electric motor and gearbox.

BioDisc units benefit from low profile GRP covers, which are sectioned to facilitate easy access access. There is also a free-standing, weatherproof control panel supplied with the BioDisc unit.

So how does it work? Here is a brief description of the various stages of the BioDisc process:

Primary Settlement Tank (PST)Sewage is received and heavier solids are separated and retained for periodic removal. Liquid levels in the PST fluctuate to accommodate incoming flow surges.

First Stage Biozone

Settled liquor moves from the PST to the first stage Biozone where it meets natural micro-organisms (biomass) which in turn colonise the surface of the polypropylene discs or media.

This first stage in the biological treatment process perfoms what is called a 'roughing stage' by absorbing fluctuations both in the Biochemical Oxygen Demand (BOD) and vitally in detergent levels which could otherwise hinder the biological action in the second stage.

BioDisc has a patented managed flow system which then transfers the liquor to Stage 2 of the Biozone at a constant rate.

Second Stage Biozone

Biological treatment conditions are now optimised at this stage since the liquid level is constant.

The media is now partially submerged and as it rotates, the biomass is immersed into the liquor for absorbtion and digestion of waste alternating with exposure to the atmosphere for oxygenation – since this is an 'aerobic' biological process the bacteria being used require an oxygen supply.

Final Settlement Tank (FST)

In this final stage liquor containing excess biomass forms as fine settled solids or 'humus'. This biomass enters the FST via a submerged transfer pipe. Humus is settled out and retained for periodic removal at the same time as the sludge in the PST.

Size Biodisc BB

Population Equivalent2 Houses 8 Bedrooms

Overall Diameter mm1995

Drain Inverts mm 450, 750, 1250

Depth invert to base mm 1400

Pipework Diameter mm 110

Sludge Storage Period 6 Months

Standard Supply Single Phase

Motor Rating 50W

Weight in Tonns 0.418

Have You Got a Grease Trap?

The Building Regulations (Approved Part H) requires any hot food premises to install BS EN1825 Grease traps /interceptors in its drain runs.Please Check Out Our Grease Trap Range Click Here

About Sewage Treatment Plants

Sewage treatment plants are rapidly becoming the non-mains drainage replacement of choice for septic tank owners. This doesn't surprise us since they represent a better environmental and durable response to the challenge of not being connected to mains drainage.Sewage Treatment Plants harness the process of aerobic digestion of bacteria - the most common form of life on the planet. As solid matter settles it gets decomposed by oxygen (hence aerobic) fed bacteria – the coarser solids need longer to be worked on and sludge of settled solids accumulates inside the plant, which will need removing at intervals (usually annually) but dependent upon the specific size and type of plant.

Largely unseen, quiet and watertight these subterranean units receive all the sewage water and waste from your home or business. They are usually made from glass reinforced plastic (GRP) so they're durable and robust. At the end of the bacterial digestion process is an effluent which is surprisingly clean and can be discharged into the ground (soakaway) or a nearby watercourse. This of course is subject to legislation and we recommend you take some time to understand the regulations that are involved.

About Klargester

Founded in 1955 and now part of Kingspan Environmental (a division of the Kingspan Group Plc) Klargester is a company with an international reputation specialising in the manufacture of packaged pollution control products. With a number of 'firsts' to its credit it has developed a range of innovative products, some of which have revolutionised methods of dealing with the treatment of sewage on sites where mains drainage is not available.As recognised leaders in the design and manufacture of off-mains drainage solutions we confidently supply and install Klargester products.Klargester Biodisc-BB IPS

| Size | |

| Domestic Population | 12 |

| Overall Height | 2160-2960mm |

| Width | 1995mm |

| Pipework Size | 110mm |

| Weight | 418kg |

£6,414.00

Ex Tax: £5,345.00

- Stock: In Stock

- Model: Biodisc_BB IPS

Available Options

Tags:

2800 litre septic tank

, 3600 litre septic tank

, 4600 litre septic tank

, alpha septic tank

, biocell

, biorock

, ceptic tank

, cesspit

, cesspools

, cylindrical septic tank

, cylindrical septic tanks

, domestic pumping station

, drainage

, drainage materials

, drainfield

, ezy drain

, klargester

, klargester biodisc

, klargester ezy drain

, klargester septic tanks

, low profile septic tank

, low profile septic tanks

, manhole cover

, percolation tests

, reed beds

, septic tank

, septic tank alarm

, septic tank bacteria

, septic tank baffle

, septic tank cesspit

, septic tank conversion unit

, septic tank cover

, septic tank emptying

, septic tank filter

, septic tank installation

, septic tank installation kit

, septic tank maintenance

, septic tank manhole cover

, septic tank prices

, septic tank problems

, septic tank repairs

, septic tank services

, septic tank soakaway

, septic tank suppliers

, septic tanks

, septic tanks price

, sewage

, sewage pipes

, sewage pollution

, sewage pumping chamber

, sewage pumping station

, sewage removal

, sewage treatment

, sewage treatment plant

, sewage treatment plant price